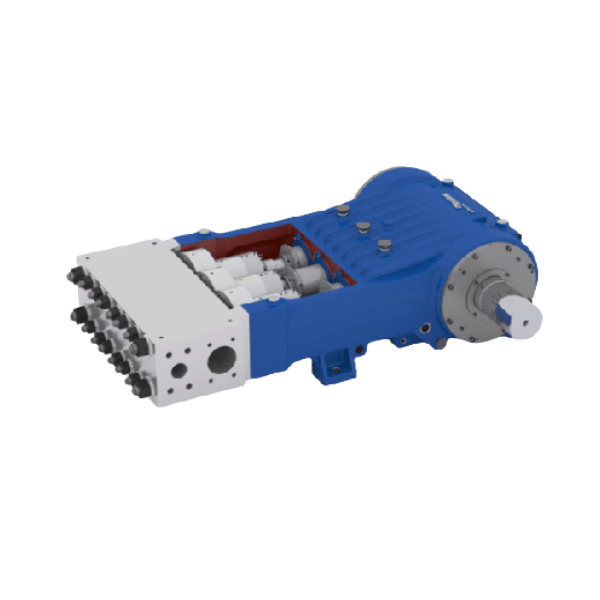

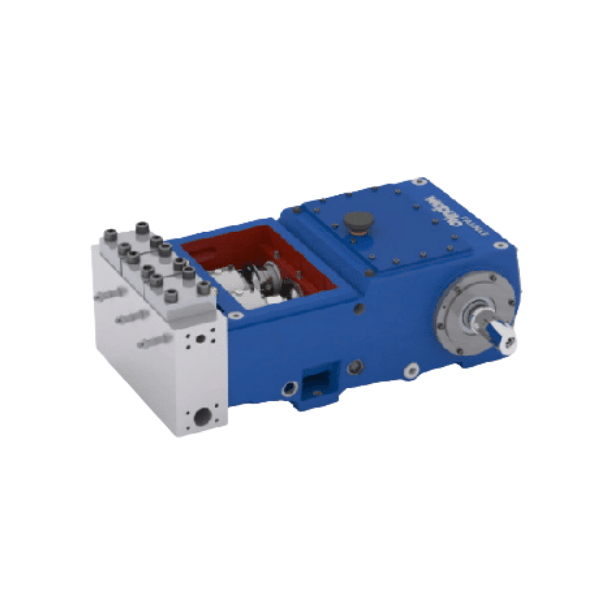

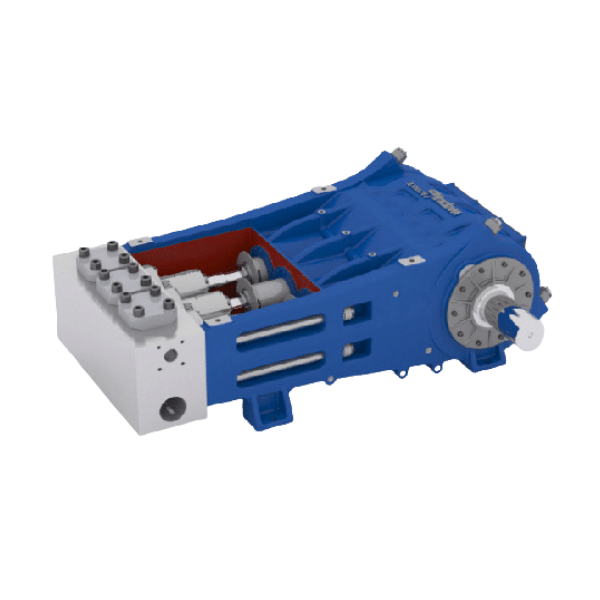

Overview Design

- Horizontal positive displacement triplex plunger pump to ISO 13710 or API 674 Standard

- Built for medium to high pressure operating with long working lifespan

- Configured to any pumpable medium with plunger seal selected to suit pumped medium

- Fluid end can be equipped with cooling or heating or flushing when required

- Drive end of the pump are designed with an integrated pressure or wiper lubrication system

- Pump can be built to meet customer pump specification for direct integration of the unit into the process system

Typical Applications

- Glycol regeneration / Gas dehydration

These pump units are for delivery of cold or hot lycol in a gas dehydration plant only. The percentage of dissolved water in natural gas from deposits is relatively high. It is humid and, therefore the gross calori c value is low

Flow Rate: Up to 150L/min (40 GPM)

Pressure: Up to 120 BAR (1750 PSI)

Fluid: Glycols (MEG, DEG, TEG)

Application: On and offshore

- Produce water / Glycol regeneration / Gas dehydration

Produced water is re-injected in order to enhance and stabilize the production of the well or simply for the disposal of water. Extremely salty water which has been separated by an upstream process is most often continuously pumped under high pressure into wells

Flow Rate: Up to 900L/min (238 GPM)

Pressure: Up to 250 BAR (3600 PSI)

Fluid: Glycols (MEG, DEG, TEG)

Application: Mixture of different fluids (seawater, oils, diesel, condense water etc..)

Application: On and offshore

- Injection Pump

Above mentioned fluids are injected in oil or gas pipelines, in order to avoid hydration of water saturated hydrocarbons, or to dissolve hydrate blockages in pipelines. Moreover, the fluids are injected into the well (pipelines) before start up and shut down. This is to avoid freezing of the dissolved water at the pipeline walls, when operation starts.

Flow rate: Up to 1200L/min (320 GPM)

Pressure: Up to 850 BAR (12300 PSI)

Fluid: Methanol, Ethanol, Glycol

Application: 95% Offshore

- Transport Pumps

Wepuko triplex plunger pumps are used to transport crude oil out of big tanks via miles long pipelines with smaller diameter, into the main pipeline.

Flow rate: Up to 2300L/min (608 GPM)

Pressure: Up to 850 BAR (12300 PSI)

Fluid: Crude oil, Hydrocarbons

Application: On and offshore

- Well Service Pumps

Well service pumps are used to carry out hydrostatic tests in risers (metallic exible pipes used in offshore application) and pipes inside the platform and oating production storage of oading ships (FPSO). Hydrostatic test means to apply internal pressure to pipes and risers during a speci c time to verify leakage or tightness of the system.

Flow rate: Up to 2000L/min (530 GPM)

Pressure: Up to 500 BAR (7200 PSI)

Fluid: Diesel, Seawater, Glycol

Application: Offshore

- Boiler Feed Pumps for Small Independent Power Plant

Wepuko plunger pumps are used in conventional power plants as primary or emergency backup feed water pumps. In smaller scale solar power plants installation as feed water and recirculation condensate pumps. The temperature in these applications can reach up to 270°c, at such demand for special material seals and connecting elements.

Flow rate: Up to 250L/min (55 GPM)

Pressure: Up to 130 BAR (1900 PSI)

Fluid: Boiler feed water

Details

| Flow Rate | Up to 3000L/min (792 GPM) |

|---|---|

| Pressure | Up to 1000 BAR (14500 PSI) |

| Application | On and offshore |

Reviews

There are no reviews yet.